Background

The exploration team at Ramelius Resources routinely uses handheld Vanta pXRF instruments on drill core and chip samples to assist geological logging and modelling. Field geologists rely on geochemical ratios directly from the instrument — for instance, Ti/Zr or Ni-Cr — to help distinguish between felsic, intermediate, mafic, and ultramafic lithologies.

Their lead geochemist also carried out lithogeochemical interpretations in IOGAS, sending results back to the team for use in modelling. This process worked well and followed strong internal procedures and metadata standards, but several pain points remained:

- Frequent data validation errors required manual fixes before uploading to the database.

- With four pXRF instruments in use, even small human errors became time-consuming to correct.

- Running classification diagrams for each batch and updating interpretations manually created delays between analyses and usable results.

While pXRF offers fast, low-cost field data, interpretation can be subjective and dependent on consistent QA/QC — something difficult to maintain manually across multiple devices and users.

Ramelius wanted to automate this workflow — from validation and QA/QC to lithogeochemical classification and database upload — so results would be available to geologists on site in near-real time.

Our Collaboration

We worked closely with the Ramelius exploration team to implement XRF-ZAP, a customised solution designed to automate validation, QA/QC, classification, and data upload.

The result: fewer errors, faster turnaround, and more consistent outcomes.

How We Did It

The XRF-ZAP platform provides an easy, step-by-step workflow for loading CSV files, cleaning data, validating results, and uploading to the database.

We tailored the platform specifically to the Vanta pXRF template used by Ramelius and aligned it with their database requirements. This included fields such as location, standard type, sample type (core or chips), and operator name.

We then added custom validation rules, prompting users to correct any errors immediately before upload.

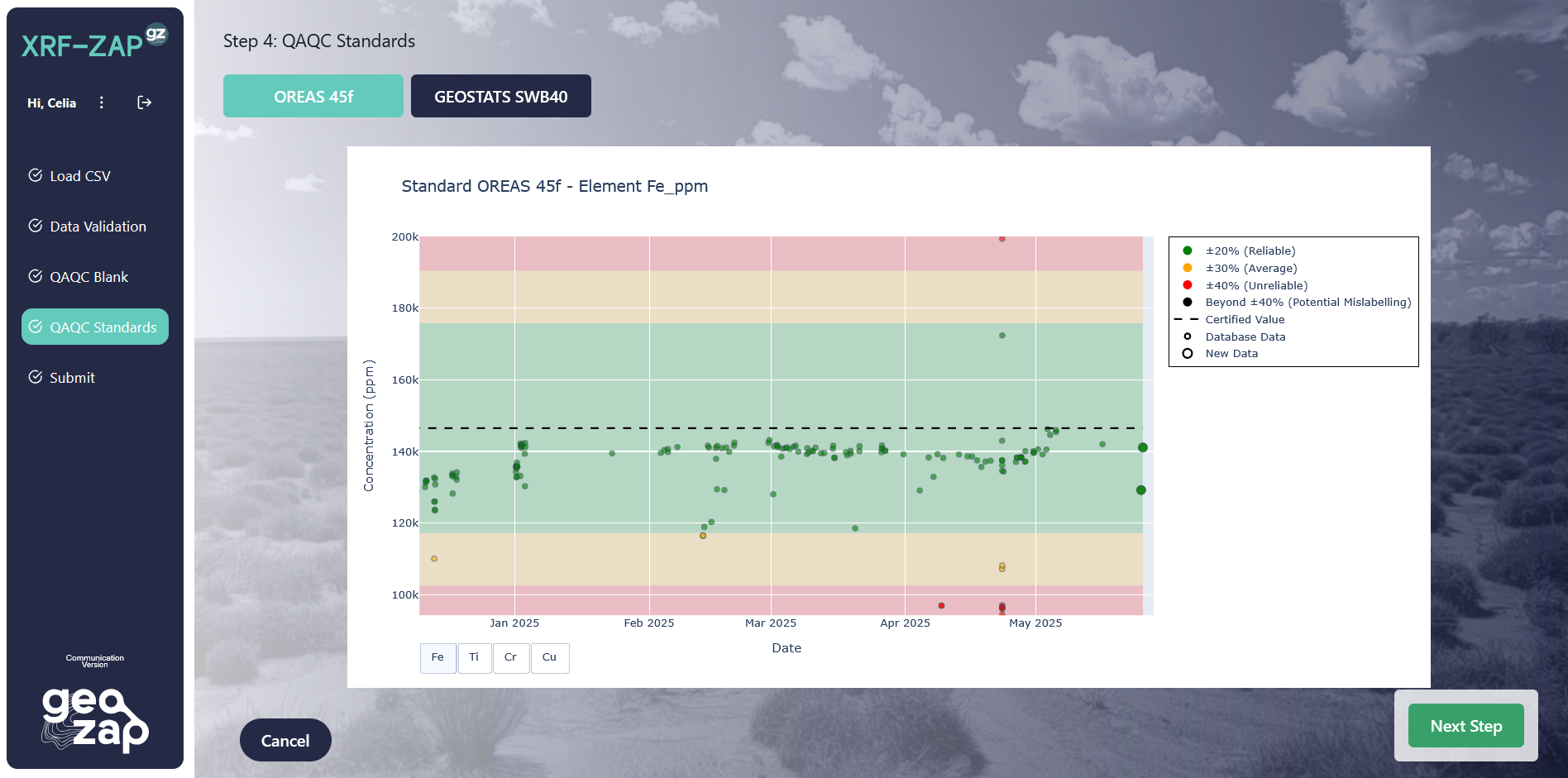

To maintain quality control, we developed an automated QA/QC dashboard:

- Blank samples are monitored for contamination.

- Standards are used to track instrument performance.

- Any anomalous results are flagged in red for review.

Once all checks pass (green lights), the operator can confidently submit validated results directly to the database — no manual intervention needed.

Lithogeochemical Classification Model

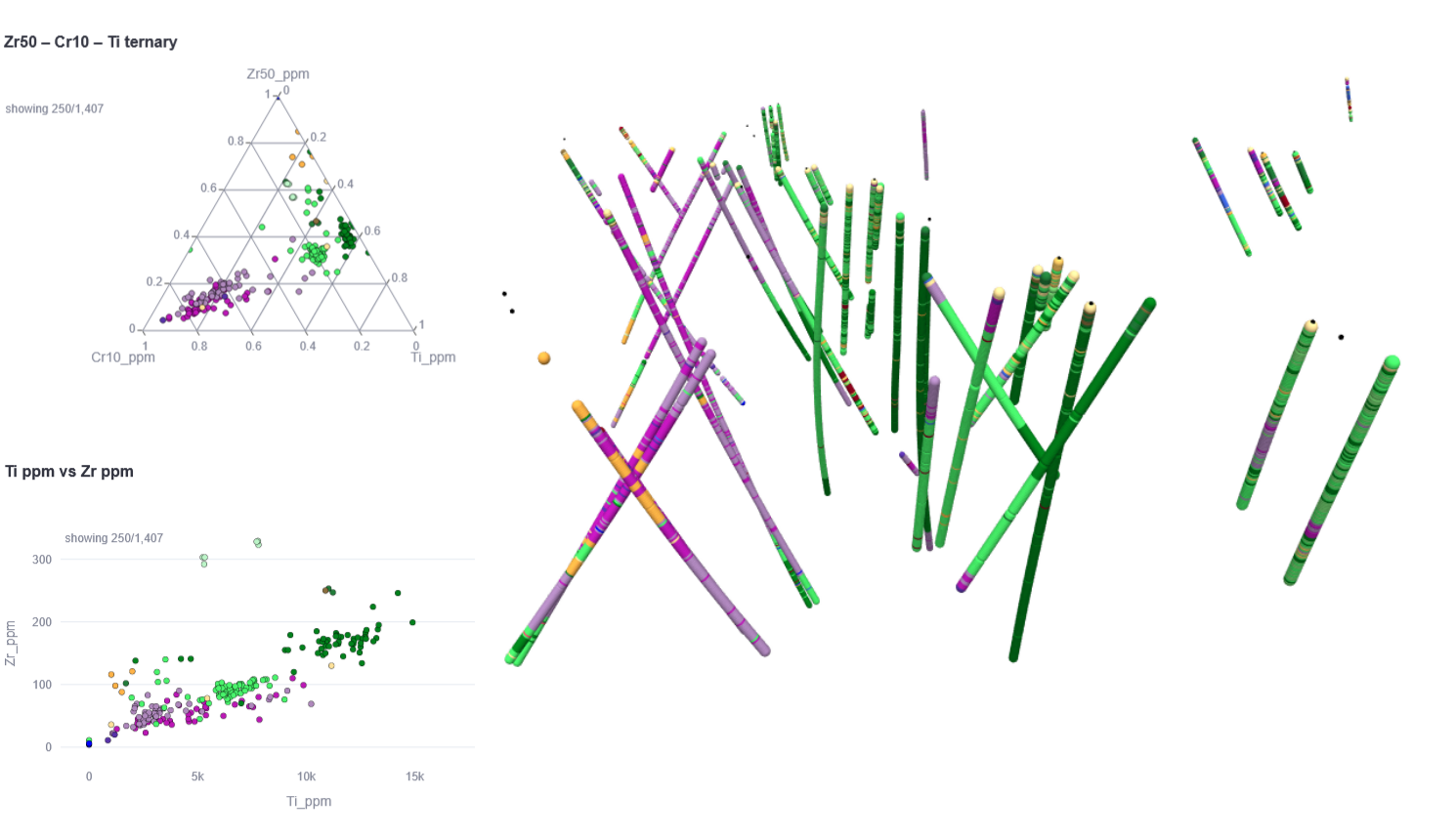

Next, we developed a custom lithogeochemical model tailored to the project’s geological setting.

We selected the most stable, immobile elements from the pXRF dataset and applied our in-house density-based clustering algorithm to identify natural geochemical domains while preserving continuity between samples.

Model parameters were tuned in consultation with the Ramelius geology team to best fit their project needs. Each cluster was then carefully geologically validated using:

- Logging data and photos of core and chips

- 2D and 3D visualisation tools

- Traditional geochemical discrimination methods

Once all parties were satisfied with the results, we finalised a custom classification model to automatically process future data uploads.

Automated Classification

From that point on, whenever an operator uploads a new CSV file through XRF-ZAP, the system automatically classifies the new samples using the established model. Results are appended to the CSV and instantly uploaded to the Ramelius database — meaning geologists can access the classified data the same day for logging and 3D geological modelling.

Key Improvements

- Fast and consistent results — no manual processing delays.

- Real-time instrument monitoring — QA/QC issues flagged immediately.

- Increased instrument utilisation — pXRF tools are now used twice as often as before, thanks to the streamlined workflow.

- Higher confidence in geological models — rapid, reliable classifications strengthen both exploration targeting and resource domaining.

Value Added

By automating data handling, QA/QC, and classification, XRF-ZAP helped Ramelius Resources move from manual interpretation to a robust, repeatable, and data-driven process.

Geologists now get immediate insights that feed directly into 3D models, supporting faster decision-making and more confident exploration targeting.

We’re proud to have supported Ramelius Resources in setting a high technical standard for pXRF data use — and we thank their team for their collaboration and commitment to innovation in exploration geology.